2023 CNC Machining Innovations: Must-Know Trends

The Rise of Advanced Materials

In 2023, CNC machining is increasingly working with advanced materials that offer superior performance and durability. These materials include composites, titanium alloys, and ceramics, which are now more accessible thanks to technological advancements in CNC machines. As industries demand components that withstand extreme conditions, the ability to machine these materials efficiently is becoming a critical trend.

These advanced materials provide significant benefits, such as reduced weight, increased strength, and enhanced resistance to heat and corrosion. Consequently, sectors like aerospace, automotive, and medical are rapidly adopting them to improve their products' performance. CNC machining innovations have enabled the precise handling of these challenging materials, leading to more reliable and efficient manufacturing processes.

Automation and AI Integration

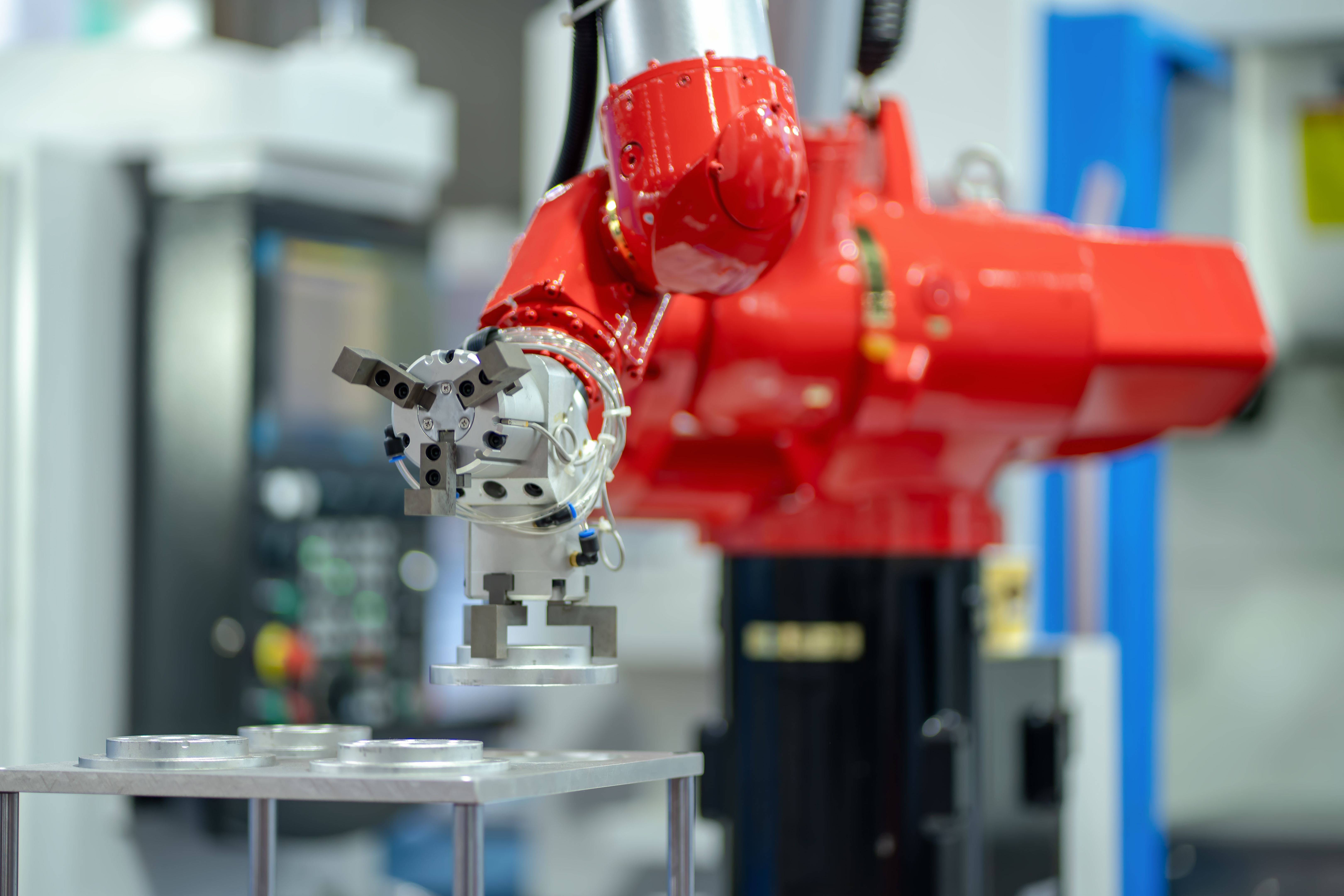

The integration of automation and artificial intelligence (AI) into CNC machining is reshaping the industry landscape. By utilizing AI-driven software and robotic automation, manufacturers can achieve unparalleled precision and efficiency. These technologies enable real-time monitoring and adjustments, minimizing human error and reducing waste.

Automation in CNC machining also enhances scalability and flexibility. With AI systems capable of learning and adapting, machines can be programmed to handle complex tasks with minimal supervision. This shift not only boosts productivity but also allows companies to meet the growing demand for customized products.

Enhanced Connectivity with IoT

The Internet of Things (IoT) is revolutionizing CNC machining by providing enhanced connectivity and data exchange. IoT-enabled CNC machines can communicate with other devices and systems, creating a seamless workflow. This connectivity ensures that all aspects of the production process are synchronized, leading to improved efficiency and reduced downtime.

With IoT, manufacturers can access real-time data analytics, enabling predictive maintenance and operational insights. As a result, companies can anticipate potential issues before they occur, ensuring consistent quality and reducing the risk of costly breakdowns.

Eco-Friendly Machining Practices

Sustainability is becoming an essential aspect of modern manufacturing, and CNC machining is no exception. In 2023, there is a strong emphasis on eco-friendly practices, such as reducing energy consumption, minimizing waste, and using sustainable materials. CNC machines are being designed with energy-efficient components and systems to lower their environmental impact.

Additionally, manufacturers are adopting recycling and material recovery processes to further lessen their footprint. By implementing green practices, companies not only contribute to environmental conservation but also improve their brand image in an increasingly eco-conscious market.

Advancements in Multi-Axis Machining

Multi-axis machining is gaining momentum in 2023 due to its ability to produce complex geometries with greater precision. Unlike traditional three-axis machines, multi-axis CNC machines can move along additional planes, allowing for more intricate designs and faster production times.

This capability is particularly beneficial for industries that require high precision components, such as aerospace and medical device manufacturing. As multi-axis machining technology evolves, it continues to push the boundaries of what is possible in CNC machining.

Conclusion

The CNC machining landscape in 2023 is marked by remarkable innovations driven by advanced materials, automation, IoT connectivity, sustainability efforts, and multi-axis capabilities. These trends are transforming how manufacturers operate, offering unparalleled precision and efficiency while meeting the demands of modern industries. Staying informed about these developments is crucial for businesses looking to remain competitive in this dynamic field.