How Automation is Revolutionizing Precision Manufacturing

The Rise of Automation in Precision Manufacturing

In recent years, automation has become a game-changer in the field of precision manufacturing, transforming traditional processes and paving the way for significant advancements. The integration of automated systems is not just a trend but a revolution that is reshaping how manufacturers operate, enhancing both efficiency and accuracy.

Automation offers numerous benefits, including increased production speeds and reduced error rates. These advantages are particularly crucial in precision manufacturing, where the margin for error is minimal. By leveraging cutting-edge technology, manufacturers can achieve higher levels of precision than ever before.

Enhancements in Production Efficiency

One of the most significant impacts of automation in precision manufacturing is the dramatic improvement in production efficiency. Automated systems can work around the clock without fatigue, ensuring consistent output and meeting tight deadlines. This capability allows manufacturers to scale operations and meet increasing demand without compromising on quality.

Moreover, automation helps streamline processes by reducing manual interventions. This not only minimizes the risk of human error but also frees up skilled workers to focus on more complex tasks that require human ingenuity and problem-solving abilities.

Precision and Accuracy Redefined

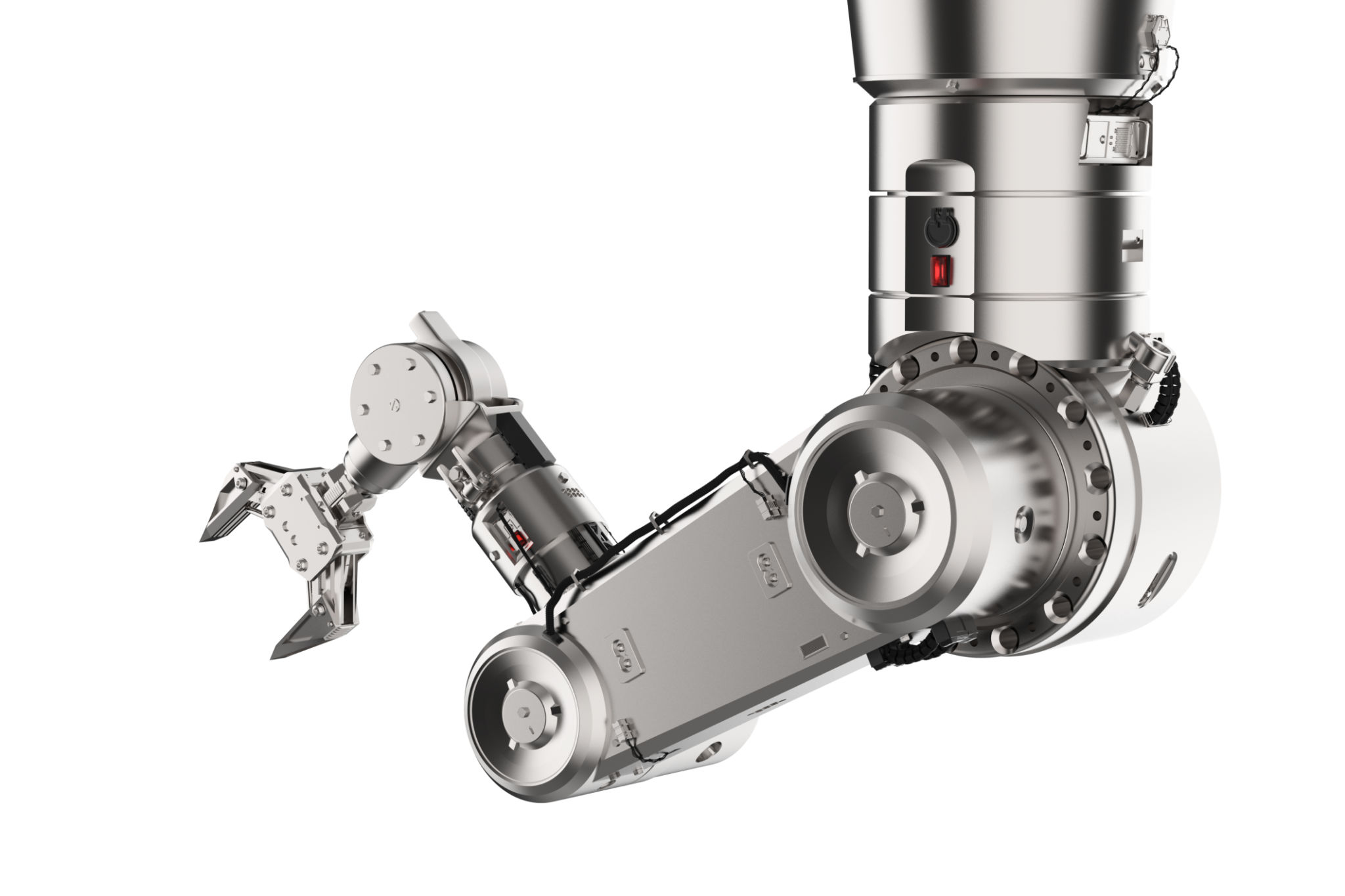

Precision manufacturing demands exacting standards, and automation plays a vital role in achieving these standards. Automated machines are capable of executing tasks with unparalleled accuracy, down to fractions of a millimeter. This level of precision is essential in industries such as aerospace, healthcare, and electronics, where even the slightest deviation can have significant consequences.

The use of robotics and computer-aided design (CAD) systems further enhances this precision, allowing for the production of complex components with intricate details that would be challenging to achieve manually. As a result, manufacturers can produce high-quality products that meet stringent industry specifications.

Cost Reduction and Enhanced Safety

Implementing automation in precision manufacturing also leads to cost savings. While the initial investment in automated systems can be substantial, the long-term benefits outweigh the costs. Automation reduces labor expenses, lowers material waste, and enhances resource utilization, ultimately leading to a higher return on investment.

Additionally, automation contributes to a safer working environment. Automated systems can handle hazardous tasks that would pose risks to human workers. By minimizing human involvement in dangerous processes, manufacturers can significantly reduce workplace accidents and ensure the safety of their employees.

The Future of Automation in Precision Manufacturing

The future of precision manufacturing is undeniably intertwined with further advancements in automation technology. As artificial intelligence (AI) and machine learning continue to evolve, automated systems will become even more sophisticated, capable of learning from data and making real-time adjustments to optimize production processes.

Looking ahead, manufacturers will increasingly adopt smart factories equipped with interconnected devices that communicate seamlessly. This connectivity will enable real-time monitoring and predictive maintenance, ensuring that operations run smoothly and efficiently.

In conclusion, automation is revolutionizing precision manufacturing by enhancing efficiency, precision, cost-effectiveness, and safety. As technology continues to advance, the integration of automated systems will only deepen, driving further innovation and setting new standards for excellence in manufacturing.